What are compaction systems used for?

Compactors and Balers are great for customers who generate high volumes of dry packaging like cardboard, paper, and plastics.

When a company starts to create high volumes of waste, compactors can become a great option and sometimes essential for companies for several reasons:

Cost savings: Waste compactors can significantly reduce waste volume, which in turn reduces the frequency of waste collection and disposal. This saves companies money as they require fewer waste collection services.

Space efficiency: By compacting waste, companies can drastically reduce the amount of storage space needed for waste before disposal. This is especially important for businesses with limited space, as it allows them to utilise their available space more efficiently.

Environmental benefits: Waste compactors contribute to a more sustainable environment. By reducing the volume of waste, they help to minimise the amount of space needed in landfills. This is crucial as landfills contribute to pollution and can have negative impacts on local ecosystems. Additionally, compacting waste leads to fewer vehicles on the road for waste collection, resulting in reduced emissions and fuel consumption.

How much weight can a compactor container hold?

When we draft a savings analysis for a customer the standard calculation is 4:1 as most compactors can compress waste into a space a quarter of is original size. The standard way for calculating how much weight a compactor container can hold is = (container size X 580 / 2000= Total Weight in Tons).

We offer 35-yard Compactor Containers therefore 35 x 580 / 2000 = 10 tonnes (roughly) is how much our containers can hold.

This calculation is based on the fact that most waste is compressed into a compactor container at a rate of between 500 and 600 pounds per cubic yard multiplied by the amount of cubic yards in a container and divided by the number of pounds in a yard.

What waste can go into a compactor container?

- Dry General Waste

- Cardboard

- Plastics

Overall, waste compactors help companies save money, make their waste management more efficient, and contribute to a greener and more sustainable environment.

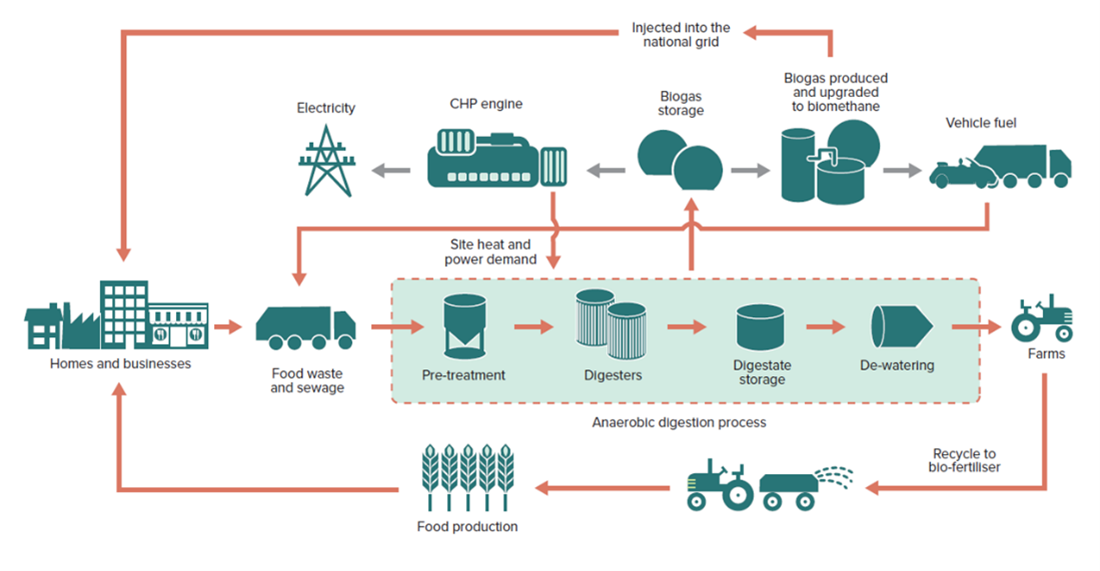

How does your food waste get converted into energy?

Part of McCarthy Marland’s company model involves collaborating with subcontractors. One example is GENeco, who share our company values of reusing waste to our environment’s advantage. We firmly believe that waste should not end up in landfills; instead, it should be processed and reused in the most environmentally friendly manner. At McCarthy Marland, we are committed to recycling or converting our waste into energy. GENeco perfectly aligns with our goals as they also recycle and reuse all their waste where possible to convert it into energy.

But how do they do this?

Biomethane has the same composition as methane derived from fossil fuels and can be used as a sustainable substitute for natural gas.

Biomethane is produced at Bristol sewage treatment works by upgrading biogas produced from anaerobic digestion – a completely natural process in which micro-organisms break down biodegradable material in the absence of oxygen.

Biomethane is used as a renewably sourced and sustainable substitute for natural gas in the local distribution network across Bristol. GENeco supply the national grid with enough gas to supply thousands of local homes and ensure our sewage treatment works is energy self-sufficient.

How it works

- Food waste is treated and pumped into a series of anaerobic digesters. The waste is heated to 32 – 42°C and kept in the digesters for 12 to 18 days. During this time, micro-organisms break down the biodegradable material in the absence of oxygen to produce methane rich biogas. At this point, the biogas contains around 60% methane.

- The biogas produced from the digesters then enters the gas to grid plant. The first stage upgrades the biogas to biomethane (~98%; 1.5% nitrogen).

- A bioscrubber removes gaseous impurities, such as carbon dioxide and hydrogen sulphide. Meanwhile the carbon filters produce virtually odour free emissions to the air.

- A small volume of propane is injected into the biomethane. This enriches the gas to natural gas quality and calorific value.

- The end product, enriched biomethane, is analysed and undergoes strict quality controls before being fed into the local gas distribution network.

- GENeco also use biomethane to power their waste collection fleet. Using biomethane in this way reduces the amount of harmful particulate matter vs diesel equivalent engines.

What are hardcore materials and what are they used for?

A hardcore material is an essential part that makes a strong foundation for building work. This type of material offers a well-compacted base that provides reassurance for the builder when infilling upper layers.

Hardcore is an indispensable solution that is necessary to raise the level of a floor, forming the lower layers of road construction that protect any surface from stresses over time. Despite pedestrian areas experiencing less stress, hardcore materials are used in the construction of pavements too, preventing bad weather and excess foot traffic from causing too much damage.

Hardcore may be used in the creation of roads, paving, driveways, foundations, ground floor slabs, and many more applications. It can also be used on its own for temporary road surfaces on construction sites. Construction waste such as gravel, crushed rocks, concrete rubble, colliery spoils, and bricks can all support the making of hardcore.

What to consider when using hardcore materials

Without the use of hardcore material, you simply can’t ensure a strong foundation for building work. A hardcore bed layer provides an invaluable solution within the construction industry, allowing floors to be raised, pavements to be laid and roads to be built.

It is incredibly important to use only high-quality hardcore due to problems that can develop if materials are not of the best standard – this type of material cannot be compromised if you want the process to be handled with punctilious care.

The choice in size of aggregates can affect the quality of the site and the draining process. If larger concrete rubble is used, as the moisture rises, the site may pool throughout the under layers – and, when frozen, the water may expand and cause cracks to the stability of the concrete overall, regardless of the material used above the hardcore material.

The hardcore will not support proper drainage if it is not of an appropriate thickness level. Materials need to be suitably thick as well as have the ability to be compressed before the upper layer is added. The thickness will prevent gaps from threatening the support of the hardcore layer.

Why recycled hardcore materials are best

At McCarthy Marland, we use recycled hardcore materials for sub-base projects. Recycling concrete can provide many benefits, especially where cost savings are concerned. Instead of purchasing new hardcore materials, you can crush and reclaim concrete on-site, saving on new material costs and haulage.

Recycled hardcore at McCarthy Marland

We provide recycled sub-base hardcore materials, which can be either collected or arranged for delivery from our recycling base in the heart of the Cotswolds in Tetbury. We sort waste deliveries for screening and crushing at our Gloucestershire recycling facility, and these materials form the base for our high-grade recycled aggregates and hardcore sub-base products.

Using recycled aggregates is a cheaper and, importantly, more sustainable alternative to aggregates that are sourced from a quarry.

We deliver recycled hardcore materials

At present we deliver Cotswold Chippings to Bath, Bristol, Cheltenham, Somerset, Chippenham, Chipping Sodbury, Cirencester, Dursley, Stonehouse, Stroud, Swindon, Tetbury, Wotton-under-Edge and Yate. We have a large coverage area spanning from Oxfordshire and Gloucestershire down to Bath and Somerset.

Our recycled sub-base is available via collection or delivery and can come in a variety of quantities, ranging from 20 tonnes to smaller skip capacities, right through to bulk bag quantities. Get in touch with us today to see how we can support you.

How to dispose of Hazardous Waste

Hazardous waste isn’t as uncommon as you might think, it can be found in everyday household items such as cleaning products and batteries. Chemicals, fuels and oils are often produced by businesses across the UK, and failing to dispose of this waste in line with compliance can cause significant harm to the environment and human health.

According to the Environmental Agency, the hazardous waste market has a total volume of 5 million tonnes of waste handled in the UK each year. Not handling hazardous waste correctly can result in large fines and even imprisonment depending on the severity of the situation at hand.

Thankfully, disposing of hazardous waste has become a relatively straightforward process over the years, making it easier for businesses to dispose of their waste and leave no excuse to pollute the environment around them. Learning how to dispose of hazardous waste correctly is the first step.

The rules around hazardous waste

Hazardous waste can not be disposed of in landfills or waste bins like general waste. Specific processes are in place to ensure the safety and wellbeing of everyone involved, which is why it is important to know that you mustn’t treat hazardous waste unless you are qualified to do so and have the appropriate facilities available.

Examples of hazardous waste include:

- Chemicals (e.g. brake fluid or cleaning products)

- Asbestos

- Solvents

- Batteries

- Hazardous waste containers

- Oils (e.g. car oil)

- Pesticides

- Items that contain ozone-depleting substances (e.g. aerosols, fridges, air conditioners)

The journey to hazardous waste disposal

Once you have indicated that your waste is hazardous, it becomes your legal responsibility to keep it safe before disposal. Keeping hazardous waste stored away while you wait to dispose of it is an essential part of the process. It must be stored in sealed containers in a separate area but close to where you would normally deal with waste.

Hazardous waste isn’t something you can take anywhere, you can only dispose of it at authorised sites where experts can collect and handle the materials for you. A classification code and the details of the hazardous materials are usually required so experts know of the risks associated with

It’s important to keep in mind that local landfills may not accept certain types of hazardous waste, particularly if it’s corrosive or flammable. Thankfully, there are still plenty of hazardous materials that can be recycled, including light bulbs, cleaning fluids, oil-based paints, garden chemicals, automobile fluids, adhesives, batteries and more. Each recycling centre will have its own rules and regulations regarding the disposal of hazardous waste, so make sure you get in touch before showing up.

While it might seem difficult to dispose of hazardous waste safely and with the environment in mind, it’s more important to consider that non-compliance can result in serious harm to both the environment and humans. Many penalties can occur if hazardous waste is not handled correctly, but following procedures can make the disposal process much easier.

At McCarthy Marland, we offer comprehensive hazardous and technical waste solutions that are compliant with all legislation. Get in touch with us today to find out more about how we can help you.

Addition to fleet

New Bell B30E dump truck delivered and put straight to work at our Somerton facility.

New Machinery fitted for our Transfer Station

We have now installed a new Baughan waste sorting line at Albert Quay in Bristol. This new technology will significantly increase the amount of recyclable material we can recover from the waste we handle in Bristol.